Lamina

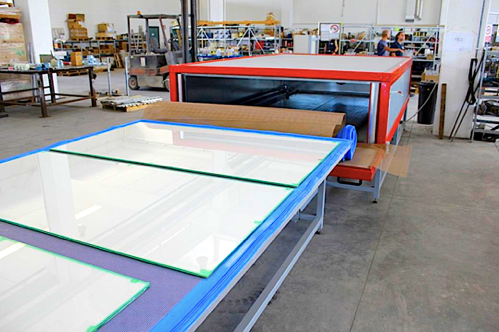

Lamina is a machine for laminating flat glass with EVA

The oven consists of a heating chamber where the housing is provided for a plane or a Multi- Storage system for increased production.

The glass loading and unloading system works by extracting the plane of an outer rail or through the use of a hydraulic platform for the Multi- Storage system.

An integral part of the system is an oil vacuum pump, connected to the silicone bag on the plane, by means of high temperature resistant

silicone tubing and related attachments to make the vacuum required for the lamination of glass.

Inside the heating chamber, the thermal cycle occurs through a hot air convection system which distributes the heat evenly throughout the chamber and across the surface of glass.

Available in sizes from 1500×3000 to 2200×4500 mm.

- Downloads/Info